-

Posts

980 -

Joined

-

Last visited

-

Days Won

15

Content Type

Profiles

Forums

Calendar

Downloads

Gallery

Posts posted by JJ the Gardener

-

-

- Natural farming section

- Indoor gardening environment

- Biochar

- Compost extract & Compost teas

- Vermiculture & Vermicompost, worm castings

- Soil recipe

- Soil Microlife

Below you find a significant library of information. It is very extensive but if you have a need to truly understand biochar. I highly recommend spending the time to get to know the information in these videos and presentations. The knowledge is extensive and rarely found in such a compilation as this. As always, if you feel a need to support, support the video makers directly.

We hope it helps you!! ~Cultural Healing and Life.

Biochar

Biochar is a carbon rich product made from any organic substance by thermal decomposition without oxygen.

Ok, its a type of charcoal that will work to stabilize soil conditions and when the soil environment is healthy and soil thrives for a long period of time the biochar plays a role in increasing soil productivity by promoting positive living conditions and soil environment for beneficial soil microbiology.

- Biochar is mainly utilized as a soil amendment, in waste management, energy generation and in sequestering carbon.

- In gardening biochar is used as a soil amendment that becomes homes homes for microorganism.

- Biochar is most effective in tropical areas due to leaching aspects of rain and runoff.

- Biochar is also beneficial in temperate areas but its benefits are more noticeable in the tropical regions or where monsoons are a factor.

- Biochar increases soil moisture and germination rates when at the 1 and 2% rate.

It can be made by a variety of methods but it is typically made from a waste products such as the manufacture of biofuels. However, Bamboo and hardwoods that are waste products are typically used in making a gardening biochar.

Depending on your soils and farming needs a combination of high ash biochar from manure and bone mixed with hardwood or bamboo biochar can be a consideration.

Biochar made from manures and bones, are mainly composed of ashes “high mineral ash biochars,” and thus can effect crops differently than hardwood biochar.

- High ash type of biochars will be a short-lived benefit as they contain less carbon compared to say bamboo and hardwoods.

Understanding the effect of the type of biochar (such as in high ash biochar or hardwood biochar) with alkaline soils to determine if biochar can impact PH as to ensure the biochar does not increase the PH to levels to cause micro-nutrient lockouts however this is not typically an issue with healthy soils as they will tend to be more PH stable.

- Essentially utilizing hardwood and bamboo biochar will have less impact in PH than high ash biochar made from manure and bone.

- Depending on soil situations a mix of biochar types could be better than one or the other alone.

Methods for making biochar vary from traditional pits in the ground, utilization of various barrel techniques and on large industrial scales.

Basically to make biochar the idea is to remove all the volatile or "fuels" in the organic substance and leave just the carbon. This is then inoculated, often with a nitrogen source and then pulverized into a powder.

One once of biochar has the surface area of approximately an American football field. This is wonderful news to microbiology.

International Biochar Initiative - Guidelines on Practical Aspects of Biochar

Application to Field Soil in Various Soil Management Systems

This video is excellent in understanding about biochar

USU Extension Forestry - Biochar Basics

USU Extension Forestry - Biochar Basics

Biochar Creation Methods

Below we illustrate various types of biochar creation and some advanced information for those who would like more information than the basics.

Biochar can be simply made in a pit, with a top lite up draft, bottom fed barrel systems and kiln systems at the farm or garden location.

- We will spend more time on pit biochar and tlud barrel systems and tlud kiln systems that can be easily constructed on site and is mobile.

Biochar can also be made in large industrial systems and larger stationary type of ovens. Mostly in this compilation we will discuss what small farmers and gardeners can create for themselves.

Traditional Pit Biochar

Toon & Leigh porpeang farm Thailand

Barrel System

Top Lid Up Draft or TLUD Barrel System

This system uses a chimney effect and the main heat for making the biochar comes from gas contained naturally in the wood. By design the gas comes from the bottom of the inner barrel and and is ignited in the outer barrel causing the necessary heat at a good temperature to make the biochar.

How to make biochar reactor - TLUD barrel

THEGREENCABBY - How to make biochar reactor - TLUD barrel

THEGREENCABBY - How to make biochar reactor - TLUD barrel

Another construction video

Guy Langlois - Building a Biochar Reactor

Guy Langlois - Building a Biochar Reactor

Small Farm Production

AnnMAugustine - Making Biochar For Small Farms

AnnMAugustine - Making Biochar For Small Farms

Making Biochar and Charcoal with the TLUD Brick Chimney Kiln

O.J. Romo - Making Biochar and Charcoal with the Brick Chimney Kiln

O.J. Romo - Making Biochar and Charcoal with the Brick Chimney Kiln

Small home garden kiln

brianzaro - TLUD stove for biochar

brianzaro - TLUD stove for biochar

Quality of testing created biochar

Quality of biochar varies due to several factors, the material used and how well the tars and resins are removed (mobile matter) that can be toxic to plants.

Their are a few ways to evaluate the quality of your biochars and should be done on home made biochar before use.

Appearance and sound

- Black and look almost like black glass.

- Biochar should almost make a clinking noise when rubbing between each other.

The soap test

- Wash hands, well made biochar will wash off easily with just water.

- If mobile matter is present then you will need to use soap to wash your hands clean. This mobile matter is from tars and resins that have not cooked off.

Germination test. (it is not necessary to inoculate biochar for the germination test.)

-

Germinate seeds in a germinating soil with and without biochar.

- Mix a bit of biochar with your germinating soil.

- Use only normal germinating soil.

- If biochar mix does not germinate it is a problem.

Worm test. Do worms avoid the biochar areas?

- If worms avoid the biochar it is not good.

- If worms like it, all is well!

Biochar water retention test

- Fill water glass 3/4 full of water

- Fill water glass 3/4 full of biochar

-

Pour water glass into the biochar glass.

- The water should not overflow and be the same level as the water.

Inoculating or priming biochar

Inoculating or priming biochar is necessary as to prevent the biochar for initially drawing nutrients into the char from the soil, this drawing effect will prevent the plants gaining access to those nutrients and can cause initial nutritional deficiencies for your plants.

Inoculate by making a liquid nitrogen source from compost/garden/compost teas, FAA and/or liquid IMO. You can tailor your inoculation to best suite your needs of the biochar.

-

Additionally you can place fresh biochar in your compost piles and spread over your animal and chicken coup floors.

- Takes longer before inoculation but it will help with controlling smells.

- Liquid IMO - http://culturalhealingandlife.com.www413.your-server.de/index.php?/topic/48-inputs-section-12-imo-4-liquid-imo/&tab=comments#comment-100

- FAA - http://culturalhealingandlife.com.www413.your-server.de/index.php?/topic/43-inputs-section-8-faa-fish-amino-acids/

- FFJ - http://culturalhealingandlife.com.www413.your-server.de/index.php?/topic/42-inputs-section-7-ffj-fermented-fruit-juice/

- Compost tea example - https://www.youtube.com/watch?v=RDVP8QPXrk0

- Ready made organic vegetative fertilizer can be used as well.

Video on different inoculation methods

THEGREENCABBY - Activate & Inoculate Biochar

THEGREENCABBY - Activate & Inoculate Biochar

Applying Inoculated Biochar

When applying biochar to soil for improving its fertility, the biochar should ideally be located near the soil’s surface in the root zone, where the bulk of nutrient cycling and uptake by plants takes place.

Certain systems may benefit from the application of biochar in layers below the root zone, for example during landscaping for carbon sequestration or if using biochar for moisture management.

- When biochar is to be applied to soil solely for carbon sequestration purposes, placement deeper in the soil, for example in new landscaping or construction areas, would be desired since microbial activity that can degrade biochar carbon is reduced deeper in the soil profile.

Biochar Bob - Biochar Bob 101: Episode 1 - How to Apply Biochar to a Garden

Biochar Bob - Biochar Bob 101: Episode 1 - How to Apply Biochar to a Garden

Biochar workshop - A must watch series full of information

Biochar Workshop Part 1, How to Make Biochar

Living Web Farms - Biochar Workshop Part 1, How to Make Biochar

Living Web Farms - Biochar Workshop Part 1, How to Make Biochar

Biochar Workshop Part 2, Why to Make Biochar

Living Web Farms - Biochar Workshop Part 2, Why to Make Biochar

Living Web Farms - Biochar Workshop Part 2, Why to Make Biochar

Biochar Workshop Part 3, The carbon cycle

Living Web Farms - Biochar Workshop Part 3, The carbon cycle

Living Web Farms - Biochar Workshop Part 3, The carbon cycle

Biochar Workshop Part 4, The biochar facility

Living Web Farms - Biochar Workshop Part 4, The biochar facility

Living Web Farms - Biochar Workshop Part 4, The biochar facility

Biochar Workshop Part 5, Biochar and the greenhouse

Living Web Farms - Biochar Workshop Part 5, Biochar and the greenhouse

Living Web Farms - Biochar Workshop Part 5, Biochar and the greenhouse

What happens to carbon after applying biochar A study in biochar.

NSW DPI Agriculture - What happens to carbon in the soil after biochar is applied?

NSW DPI Agriculture - What happens to carbon in the soil after biochar is applied?

Test results using biochar

ebsmsa - Field Test Biochar with Corn and Sunflowers (final)

ebsmsa - Field Test Biochar with Corn and Sunflowers (final)

Test without inoculating char over time period of 3 years

SkillCult - Leeks in Biochar Test Bed Much Larger and Greener

SkillCult - Leeks in Biochar Test Bed Much Larger and Greener

BONUS SECTION

Biochar and Hugelkultur in a food forest

The Natural Farmer - John Kaisner The Natural Farmer - Tropics - #15 Food Forest with Biochar Hugelkultur

The Natural Farmer - John Kaisner The Natural Farmer - Tropics - #15 Food Forest with Biochar Hugelkultur

Biochar and Charcoal differences

There is a difference in how biochar and regular charcoal is made. Biochar is made for use in agriculture. It is specifically pyrolized or charred to support the improvement of soil. Charcoal can have additive binders and/or tars and resins that are not agriculturally compatible as the charcoal product is going to be optimized for its energy value

Biochar is considered sustainable due to utilization of waste resources and the carbon sequestering aspects but charcoal will release into the air instead of being stored in the soils. In addition Charcoal production is classically an unsustainable trade, and one of the biggest drivers of deforestation, particularly in developing country contexts. Commercial charcoal products, as I mentioned before, are often petroleum-based—another unsustainable, unrenewable resource.

Carbon storage is different between charring and burning. Burning is a combustion reaction of combustible material in the presence of air (nitrogen and oxygen), but charring is a degradation of material due to heating in absence of oxygen.

The products from burning and charring are also different. The burning of plant matter produces carbon dioxide and water; whereas, charring produces a complex form of carbon and low molecular weight compounds (smoke).

Burning charcoal returns carbon, as part of carbon dioxide (27%) gas to the atmosphere, however, charring returns carbon to the land as a solid, char.

Biochar and Activated Carbon differences

- Biochar is a precursor to activated carbon.

- Activated carbon has a heavy carbon footprint and is expensive to make and utilized chemicals.

- For information please visit this link: http://fingerlakesbiochar.com/biochar-vs-activated-carbon/

- The following video is listed as to illustrate activated carbon creation.

How to make survival activated charcoal

PHOENIX SURVIVAL - Survival Activated Charcoal Made Naturally

PHOENIX SURVIVAL - Survival Activated Charcoal Made Naturally

Summary

Biochar is just simple carbon with great potential benefit when utilized correctly. When it is not it may not be the benefit, at least initially that many have made it out to be.

The commercialism of biochar has sort of made biochar appear like a super hero amendment but biochar works best for improving poor soils and maintaining soil environments over long periods of time with proper management and technique.

Due to that aspect we have created this compilation as to better impart realistic information and knowledge regarding biochar. We hope that this work helps you, your soils, your plants and the environment.

A song for you!

Credits - Please support these below directly.

- OMC VIDEOS - Old Man Canyon - Wiser

- http://www.biochar-international.org

- USU Extension Forestry

- Climate State

- THEGREENCABBY

- SkillCult

- Living Web Farms

- Guy Langlois

- O.J. Romo

- AnnMAugustine

- PHOENIX SURVIVAL

- The Natural Farmer

- Scott Laskowski

- Ultra Compost

- brianzaro

- ebsmsa

- NSW DPI Agriculture

- Biochar Bob

- Swedish House Mafia - Save The World

- The School of Life

Links:~ A Proud Cultural Healing and Life Compilation

-

Natural Farming Inputs

- Introduction to Natural Farming

- LAB - Lactic Acid Bacteria

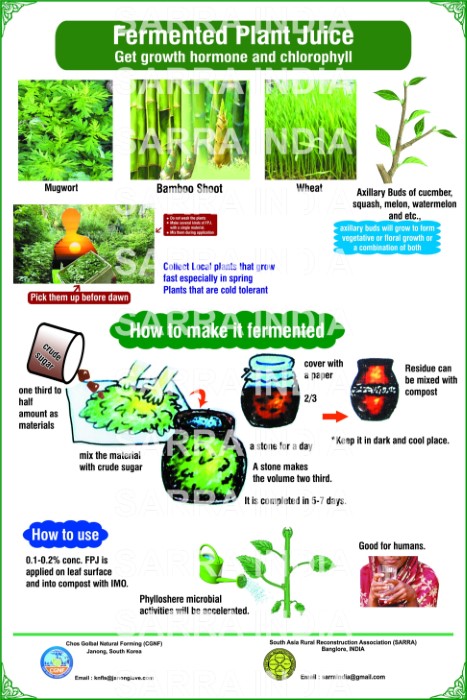

- FPJ - Fermented plant juice

- Seawater, Fermented Seawater, Bio Mineral Water

- Vinegar

- OHN - Oriental Herbal Nutrient

- WCA - Water Soluble Calcium

- WCAP - Water Soluble Calcium Phosphate

- FFJ - Fermented Fruit Juice

- FAA - Fish Amino Acids

- S.E.S. - Seed and Seedling Treatment

- IMO to IMO2

- IMO 3

- IMO 4 & Liquid IMO

- IMO 5

- Preserving bacterial based inputs

Inputs - Section 13 - IMO 5

IMO 5 is essentially taking a nitrogen rich source such as manure, compost, food scraps, bone meal for example and using IMO4 to break it down to a usable media that will not harm plants nor lose or lose as much nitrogen due to the nitrogen cycle compared to other traditional mainstream farming methods.

- Not only is IMO5 ideal for plants but also the environment.

Chris Trump - How To IMO5

Chris Trump - How To IMO5

IMO 5 Ingredients

- IMO4

- Nutrient rich material such as compost, food scraps, manure, bone meal, etc.

- FPJ 1:500

- BRV 1:500

- OHN 1:1000

- SW 1:25

- Humic acid 1:500

- Water "approximately" 1GAL/25LB

My wife and I met the base player of Deep Purple from when this song was made. I post in loving memory of my wife.

IMO 5 Process

How much moisture to add will vary depending on how dry or moist the IMO4 is.

-

Create your IMO5 water solution

- Per gallon of water

- FPJ 1:500

- BRV 1:500

- OHN 1:1000

- Sea Water 1:25

- Humic acid 1:500

- Mix the IMO4 and the compost, manure or whatever media you are using

- Make a divot into the middle of the mixed soil & added dry materials.

-

Then mix in the IMO5 water solution

- Pour water solution into the divot.

- Mix very well and repeat until evenly mixed.

-

Careful not to make too wet or the temperature will increase (130f to 140f temperature is too high).

- Manure and high nitrogen additions keep more dry than wet.

- Mix so the media holds slightly together but crumbles apart, it should not clump or hold its shape.

- In about 7 to 10 days the IMO5 will be ready to use.

Application

Use IMO-4 by top dressing the soil around plants and top dressing fields before planting.

Chris Trump - How to apply IMO4

Chris Trump - How to apply IMO4

Why to Natural Farm

“Farmers have lost their independent authority which they have in the farming techniques of the old days.

Farmers became dependent in buying almost everything that they need in farming, and they just engaged in farming by role according to the program presented by the seller.” “I insist to recover the spirit of farmers.

- To achieve it is impossible until the exhilarated farming that farmers can recover subjectivity in the farming technique is realized.”

“New vision of farming techniques is needed to recover the true nature of farming. There is a hidden possibility to realize a new vision in the ways that farmers make and apply which are necessary farming materials by making use of local materials actively.”

Dr. Han Kyu Cho

A word from us.

Cultural Healing and Life has compiled this information in the hopes that it will help not just to grow high quality plants and trees but that we begin to heal the lands and soils and by working from the bottom of the food chain up can nutritionally begin to heal ourselves. We see the microorganisms as part of the food chain that proactively works to increase the mineral density of our food and thus we increase the brix levels of our plants and the health of our animals. In so doing, we can restore true nutritional health.

It has been a pleasure compiling this and it is with respect and gratitude that I thank all those who were used in this compi`lation. Please support them directly.

~Cultural Healing and Life, JJ the Gardener.

Credits

- Dr. Han Kyu Cho

- Chris Trump

- http://www.cgnfindia.com/index.html

- The School of Life

-

Reggaeville - Natali Rize - One people

Natural Farming Inputs

- Introduction to Natural Farming

- LAB - Lactic Acid Bacteria

- FPJ - Fermented plant juice

- Seawater, Fermented Seawater, Bio Mineral Water

- Vinegar

- OHN - Oriental Herbal Nutrient

- WCA - Water Soluble Calcium

- WCAP - Water Soluble Calcium Phosphate

- FFJ - Fermented Fruit Juice

- FAA - Fish Amino Acids

- S.E.S. - Seed and Seedling Treatment

- IMO to IMO2

- IMO 3

- IMO 4 & Liquid IMO

- IMO 5

- Preserving bacterial based inputs

~ A Cultural Healing and Life Compilation

-

Natural Farming Inputs

- Introduction to Natural Farming

- LAB - Lactic Acid Bacteria

- FPJ - Fermented plant juice

- Seawater, Fermented Seawater, Bio Mineral Water

- Vinegar

- OHN - Oriental Herbal Nutrient

- WCA - Water Soluble Calcium

- WCAP - Water Soluble Calcium Phosphate

- FFJ - Fermented Fruit Juice

- FAA - Fish Amino Acids

- S.E.S. - Seed and Seedling Treatment

- IMO to IMO2

- IMO 3

- IMO 4 & Liquid IMO

- IMO 5

- Preserving bacterial based inputs

Inputs - Section 12

IMO 4 & Liquid IMO

Korean Natural Farming How to : IMO 4

Chris Trump - Korean Natural Farming How to : IMO 4

Chris Trump - Korean Natural Farming How to : IMO 4

IMO 4

-

Mixing should be done on the soil floor and not on concrete in a heap of this mixture not more than 20 cm in height.

-

Mix 1 part IMO 3 to 1 parts rice bran

-

-

Now mix one part IMO 3 with one part soil.

- 50% of the soil should be from the crop field and 50% should be from fresh new soil (mountain soil, red fine clay, etc).

- Mixing the soils will harmonize the imo and soils.

-

To control moisture "best practice" using natural farming inputs.

-

When needed, control moisture with Natural Farming inputs such as FPJ, FFJ, FAA, Lab, Sea Water.

-

Ratio of 1:1000 dilution with diluted seawater.

- It is necessary to add sea water for the IMOs to work best, when they are inoculated to the soil.

-

Ratio of 1:1000 dilution with diluted seawater.

-

When needed, control moisture with Natural Farming inputs such as FPJ, FFJ, FAA, Lab, Sea Water.

- Keep the mixture covered for two days.

- The end product is called IMO- 4.

Pro Kashi IMO 3-4 Video, very good video showing how to know when it is done.

Click for emoji for video

HOW TO STORE IMO- 4

- Moisture may be evaporated during storage.

- Adjust the moisture content to 65-70% by adding nutrient liquids of natural farming inputs just before using IMO-4.

Application

Use IMO-4 by top dressing the soil around plants and top dressing fields before planting.

Chris Trump - How to apply IMO4

Chris Trump - How to apply IMO4

HOW TO UTILIZE IMOs

In order to be effective, IMOs should be used in a proper manner.

Use IMOs continuously. Since IMOs are used to make soil fertile and healthy, these should be collected and prepared every year. In order to bring about continued results. IMOs must be maintained in the soil.

Maintain IMO diversity. Avoid being choosy in collecting microorganisms. Instead, microorganisms from different environments should be collected and mixed. It is recommended to collect IMOs from all four directions of the field. We can also collect microbes from mountain, summit, valley and trench.

To obtain strong microbes obtain from areas that has distinct environmental conditions.

- For example, the sunny side of the field will have different IMOs from the shaded side.

- Altitude will also affect the variety of microorganisms at every level.

- To include "tough guys" into the IMO mixture, samples from the high mountains or uncontaminated regions can also be collected.

Liquid IMO

Chris Trump - How to Liquid IMO with Chris Trump

Chris Trump - How to Liquid IMO with Chris Trump

Ingredient list for LIMO:

- IMO3 or Imo2 or IMO4 can also be used.

- FPJ 1:500

- BRV 1:500

- OHN 1:1000

- SW 1:25 (1:20 is ok too)

- Humic acid 1:500 (optional)

- Fulvic acid 1:2000 (optional)

- Brown sugar 1:1500 (by volume, optional)

- Water (non-chlorinated)

Liquid cultures of IMOs is similar to brewing a compost tea.

-

Fill a pair of fine net bag with IMO3.

- Pantyhose

- Paint strainer bag

- Room temperature of around 20 degrees C and a PH between 6 and 7 is sufficient.

- You will then need a 250L opaque container with an air compressor.

-

Add inputs at

- 0.5L Lactic Acid Bacteria (LAB),

- 2L Fermented Plant Juice (FPJ),

- 700-800 grams of brown sugar to 150-160L of water.

-

Turn on air pump and and put the IMO 3 in the solution.

- Making IMOs and making actively aerated compost teas are similar but the main differences seem to be the source materials and the IMO fermentation process as opposed to composting.

-

Depending on the the culture temperature the fermentation process takes between 5 and 7 days in Spring and Fall and 10 and 30 days in winter.

- Depending on the cultivated state the resultant mixture can smell either sweet or nasty,

- Sweet smell is desirable.

-

Often a sludge will appear on the surface. This sludge is composed of microorganism corpses.

- This can occur when food or air is lacking in the solution.

- If it occurs add more air, and/or add more FPJ.

-

Replacing the IMO in the sack every once in a while can also be beneficial.

- Compost removed IMO 3

- Refill the tank with water while adding more food for microorganisms. The basic dilution is 1000 times, but can be as strong as 500 times depending on the need.

- Regular Dilute rate is 1:1000 with water when using.

Using LIMO

- Use the same way you would a compost tea or garden tea.

- Foliar spray or with treat soil before planting or anytime you need to increase the biology.

Additional, you can utilize chemical fertilizers and liquid IMO.

-

Chemical fertilizer can be added to the solution.

- The solution can then be used 7-10 days later after the IMO has had time to act on the chemicals.

-

Adding too much chemical fertilizer at once can stop the fermentation process.

- Introduce the chemical fertilizer to the tank in adequate amounts slowly.

- The yeast bacteria abundant in FPJ are excellent decomposers of chemical fertilizers converting them to easily absorbable mineral forms.

-

Using chemical fertilizer in this way will greatly reduce soil degradation and the nutrients will also be better absorbed by plants.

- To duplicate the effect of nitrogen use ammonium sulphate or urea.

- To duplicate the effects of phosphorus, use superphospate or double superphospate.

- To duplicate the effects of calcium use quick lime.

Credits

- Chris Trump

- http://www.cgnfindia.com/imos.html

- http://www.kswcd.org/conference/Dr Hoon Park III - Indigenous Microorganism(IMO).pdf

- https://rooftopecology.wordpress.com

Natural Farming Inputs

- Introduction to Natural Farming

- LAB - Lactic Acid Bacteria

- FPJ - Fermented plant juice

- Seawater, Fermented Seawater, Bio Mineral Water

- Vinegar

- OHN - Oriental Herbal Nutrient

- WCA - Water Soluble Calcium

- WCAP - Water Soluble Calcium Phosphate

- FFJ - Fermented Fruit Juice

- FAA - Fish Amino Acids

- S.E.S. - Seed and Seedling Treatment

- IMO to IMO2

- IMO 3

- IMO 4 & Liquid IMO

- IMO 5

- Preserving bacterial based inputs

~ A Cultural Healing and Life Compilation

-

Americans paying more in taxes than for food, clothing

By Brooke SingmanPublished August 31, 2017

Fox News Source: http://www.foxnews.com/politics/2017/08/31/americans-paying-more-in-taxes-than-for-food-clothing.html

Americans spent more money on taxes than they did on food and clothing last year, according to data released earlier this week.

In an assessment of “Consumer Expenditures” for 2016, the Bureau of Labor Statistics showed the average bill for federal, state and local taxes was $10,489.

By comparison, Americans spent $9,006 on food and clothes, with most of that going toward food.

CNSNews.com first pointed out the findings. While it may not come as a surprise that American households are shelling out to Uncle Sam, the data showed that bill has risen sharply in recent years -- the average tax bill rose 41 percent overall since 2013.

According to the BLS, federal income taxes rose from $5,743 to $8,367 in that period. State and local income taxes rose from $1,629 to $2,046.

The stats come as President Trump prepares to pressure Congress to pass tax reform. In a Missouri speech on Wednesday, he called for simplifying the system and lowering rates.

"This enormous complexity is very unfair," the president said. "It disadvantages ordinary Americans who don’t have an army of accountants while benefiting deep-pocketed special interests."

According to BLS, the largest expense for Americans in 2016 was on “housing,” costing an average consumer unit $18,886 during the year.

Brooke Singman is a Politics Reporter for Fox News. Follow her on Twitter at @brookefoxnews.

-

Natural Farming Inputs

- Introduction to Natural Farming

- LAB - Lactic Acid Bacteria

- FPJ - Fermented plant juice

- Seawater, Fermented Seawater, Bio Mineral Water

- Vinegar

- OHN - Oriental Herbal Nutrient

- WCA - Water Soluble Calcium

- WCAP - Water Soluble Calcium Phosphate

- FFJ - Fermented Fruit Juice

- FAA - Fish Amino Acids

- S.E.S. - Seed and Seedling Treatment

- IMO to IMO2

- IMO 3

- IMO 4 & Liquid IMO

- IMO 5

- Preserving bacterial based inputs

Inputs - Section 11

IMO 3 Cultivated Indigenous Microorganisms

IMO 3 is essentially a concentrated stock of cultivated indigenous microorganisms that is then placed into a dormancy state that can be furthered processed into liquid IMO and imo 4.

IMO 3 with Chris Trump

Chris Trump - IMO #3 (part 1) with Chris Trump.

Chris Trump - IMO #3 (part 1) with Chris Trump.

This is a short video about the finishing/end day of IMO #3. If you using this method then this is a great little informative section on what IMO3 looks like as it finishes. By Chris Trump.

Chris Trump - How to : IMO 3 (Part 2) with Chris Trump

Chris Trump - How to : IMO 3 (Part 2) with Chris Trump

Materials for IMO 3

- IMO2

- Rice bran or similar media on which the microbes will grow

- FPJ 1:500

- BRV 1:500

- OHN 1:1000

- SW (sea or mineral water) 1:30

- Humic acid 1:500

- Water (non-chlorinated) approximately 1GAL/25LB

IMO 3 Method

- Dilute IMO-2 with water (1:1000) and mix with rice bran or flour.

- Use diluted natural farming inputs such as FPJ, FAA, OHN, plus some humic acid while adding water.

- After evenly mixing with diluted IMO-2

-

This process is very important and must be done on a soil floor and not on a concrete floor and in a place with good ventilation.

- As time passes, the temperature rises within the pile of the rice bran mixture, because it undergoes fermentation.

-

On a dirt floor make a heap 13-15 inches (30 to 40 cm) height, and cover it with straw, straw mat or leaf litter to prevent moisture evaporation and to provide shade from direct sunlight.

- 70% shade and 30% light is recommended, since it creates favorable conditions for useful microbes in paddy straw, Microorganisms such as Aspergillus’s oryzae, Bacillus subtilis, etc.

-

Be sure to press several spots with weights or soils over the straw,

- This is due to straw being too light to be fixed on the top of the rice bran mixture.

- It is best to use straw mats or straw bags (gunny bags) for covering.

- The moisture level can be measured by forming a rice bran ball and twisting it.

- If the moisture level is around 65 -70 % the ball can be easily divided into two halves.

- However, it is better to use the moisture meter (hygrometer) to get accurate data.

-

When the temperature reaches 40-50 °C

- Turnover the rice bran mixture evenly so that the temperature does not rise further and also in order to prevent moist clusters.

-

If the temperature is below 40 °C,

- The mixture may be in an anaerobic condition due to the excessive moisture.

-

If the temperature rises up above 70 °C,

- Proteins may be broken down by thermophilic microbes and nutrients released into the air resulting in loss of fertilizer effect.

- Turn over the rice bran mixture in order to control temperature. It takes about 7 days for this process.

- Cultivation speed can vary depending on the outside temperature, but it usually takes 5-7 days for the surface to be covered with whitish IMO spores.

- When the temperature stops rising the fermentation process is finished and you have IMO3.

Chris Trump - IMO #3 with Chris Trump. Natural Farming on our farm.

Chris Trump - IMO #3 with Chris Trump. Natural Farming on our farm.

Storing IMO 3

- Keep the IMO 3 bags in shaded and cool place.

- Make sure that the air is well circulated by keeping IMO-3 in a ventilated container such as jute / gunny / cloth bags.

- Spread rice straw or leaf litter at the bottom of the container,

- Place in IMO-3.

- During storage, the IMO-3 may become dry (moisture level 20-30%) as the moisture gets evaporated.

- It means that the IMO had entered a state of dormancy.

- Pile up containers into 3 layers and shield them from direct sunlight and rain.

- At this point, there is no need to turn over, because of the convection currents that are created through the gaps of containers.

- Can be stored for 6 months to a year.

Credits

- Chris Trump

- https://rooftopecology.wordpress.com

- http://www.cgnfindia.com/imos.html

- http://www.kswcd.org/conference/Dr Hoon Park III - Indigenous Microorganism(IMO).pdf

- The School of Life

- The Revivalists

Natural Farming Inputs

- Introduction to Natural Farming

- LAB - Lactic Acid Bacteria

- FPJ - Fermented plant juice

- Seawater, Fermented Seawater, Bio Mineral Water

- Vinegar

- OHN - Oriental Herbal Nutrient

- WCA - Water Soluble Calcium

- WCAP - Water Soluble Calcium Phosphate

- FFJ - Fermented Fruit Juice

- FAA - Fish Amino Acids

- S.E.S. - Seed and Seedling Treatment

- IMO to IMO2

- IMO 3

- IMO 4 & Liquid IMO

- IMO 5

- Preserving bacterial based inputs

~ A Proud Cultural Healing and Life Compilation

-

Natural Farming Inputs

- Introduction to Natural Farming

- LAB - Lactic Acid Bacteria

- FPJ - Fermented plant juice

- Seawater, Fermented Seawater, Bio Mineral Water

- Vinegar

- OHN - Oriental Herbal Nutrient

- WCA - Water Soluble Calcium

- WCAP - Water Soluble Calcium Phosphate

- FFJ - Fermented Fruit Juice

- FAA - Fish Amino Acids

- S.E.S. - Seed and Seedling Treatment

- IMO to IMO2

- IMO 3

- IMO 4 & Liquid IMO

- IMO 5

- Preserving bacterial based inputs

Inputs - Section 10

IMO - Cultivated Indigenous Microorganisms

Natural farming is based around creating a soil environment and healthy microbiology which enables the Microorganisms to play an important role in making quality soil for growing plants. These microorganisms can also be collected and cultured.

EnigmaVEVO - Enigma - Return To Innocence

EnigmaVEVO - Enigma - Return To Innocence

Microorganisms have two major functions in farming

Microorganisms decompose complex organic compounds such as dead bodies of plants and animals and wastes into nutrients, making them easily absorbed by plants.

- They can create compounds such as antibiotic substances, enzymes and lactic acids that can suppress various diseases and promote healthy soil conditions.

- Act as a catalysis for natural chemical processes in the soil.

IMOs are used primarily to create fertile and healthy soil condition that is ideal for farming and to prevent plant diseases. In Natural Farming, IMOs are used in treatments applied to the soil in order to improve its fertility and health. By collecting and making IMO's we can create not just healthy growing media but also heal sick land and begin to restore nature at its core.

All about IMO by Chris Trump

Chris Trump - All about IMO

Chris Trump - All about IMO

Cho Global Natural Farming(CGNF) - Dr. Hoon Park PDF - IMO from University of Hawaii

Indigenous Microorganisms: Grow Your Own Beneficial Indigenous Microorganisms and Bionutrients In Natural Farming

Dear Future Generations, Sorry

Gabriel Greiner - Dear Future Generations, Sorry.

Gabriel Greiner - Dear Future Generations, Sorry.

About collecting IMO

Indigenous microorganisms from the environment

Natural farming promotes the use of Indigenous Microorganisms (IMOs). The microorganisms that have been living in the local area for a long time are best for farming because they are very powerful and effective.

- They have survived and can survive the extreme climatic conditions of the local environment much better than artificially produced microorganisms

- Microorganisms (microbes) may be cultured at any time of the year; however, avoid wet, rainy seasons.

The collection process takes approximately 7–10 days in cooler weather (Below 68°F, 20°C) and 3–4 days under warmer conditions ( above 68°F, 20°C).

- Organisms that are found under the heat of the sun are largely different than those found in shaded areas such as under the bamboo trees.

- Dr. Cho advocates that it is better to culture microorganisms from different areas in order to collect different kinds of microorganisms.

Beneficial microbes are highly concentrated under undisturbed forests or other vegetated areas. Combining microbes collected from multiple sites will likely result in a more robust culture.

- It is also good to culture microorganisms at different weather conditions and to mix different types of microorganisms.

It will take 3 days in summer and 5 days in winter.

- Black molds on the steamed rice indicate that you have exceeded the number of days.

The collected IMO should smell like yeast.

Excellent illustration and overview of collection & making of IMO 1 and 2, the videos below are more detail.

Chris Trump - How to: IMO 1 and 2 on our farm

Chris Trump - How to: IMO 1 and 2 on our farm

Selecting collection sites

Collect from a variety of sources and areas, going higher up in elevation from the planting area. This works to ensure that you are collecting stronger microbiology.

-

Select areas in forests and fields.

- Old trees

- Old areas of growth.

- Areas of good mycelium growth.

-

Collecting from sites that are not nutritionally rich is better than high nutrient areas.

-

This is how to collect stronger microorganisms as only the stronger microbes can survive those areas.

- Collect near the roots of bamboo and leaf molds from broad leaf trees and plants.

- Leaf molds showing white hypha.

-

This is how to collect stronger microorganisms as only the stronger microbes can survive those areas.

-

Avoid places of regular human activity. Secluded areas are best.

- The idea of taking from famous sites may not be an ideal location if the microbiology is not healthy and strong. Select locations for merit only.

Making of a collection box

-

Made of Wood or Bamboo is recommended, preferably made of cedar.

- A small wooden/bamboo box, 12 x 12 x 4 inches deep.

- Cedar is preferred as it helps against pest.

- Ensure small holes or gaps on the bottom to promote microbiology ease to rice.

Collection Box Building videos

- Special thanks for not just illustrating how to build the IMO box but also stressing tool safety!

Guardeners of the Land - IMO box build

Guardeners of the Land - IMO box build

How to: IMO 1

Chris Trump - How to: IMO 1

Chris Trump - How to: IMO 1

IMO Collection Process

-

Fill the wooden box with 3 inches of steamed rice.

-

Prime the rice (optional)

- Add 1ml of OHN and 2ml of FPJ

-

Prime the rice (optional)

-

Ensure rice is not overly wet but more not quite done or harder.

- Allows adequate air supply by not stuffing the rice higher than 3 inches.

- Excessive moisture promotes growth of fungi that are less desirable for the intended uses.

- Fill rice half way with rice.

- Cover the box with white paper towel, being careful not to let the towel touch the rice.

-

There should be at least an inch or so of air space between the rice the paper towel.

- Loosely place rice in the box ensuring not to press the rice hard into the box.

- Without sufficient supply of air, the anaerobic IMOs will get collected.

-

Use rubber bands around the top of the box to secure the paper towel in place.

- Label date and area collected.

- Cover the top of the box with wire screen to prevent animals from tampering with the rice.

- Top the wire with a sheet of clear plastic to protect the box from rain, and place it under trees or in another secluded area.

-

The box should not be in direct sunlight or water.

- Cover with leaves or plastic.

- Mark an area 12 inches x 8 inches in the soil and make a 2 inch pit into the soil.

- Place the rice-filled wooden box in this pit, where IMOs abound, such as in a forest and/or field or at the site where many decomposed leaf molds are found. Cover the box with leaves.

- Cover the box with fallen leaves from the harvest location.

- Anchor the plastic sheet on all sides with small rocks to prevent it from being dislodged by wind.

-

Leave the box undisturbed for a minimum of 4–5 days.

- After that time, check to see whether the moist rice is covered with white mold.

- It will take 3 days in hot summer and 5 days during cooler time periods.

-

If mold growth is sparse, re-cover the box and wait an additional 2–3 days before re-checking.

-

If the mold is a color other than white (other colors indicate growth of less effective fungi).

- Multi colors are normal and usable.

- You want to more white and grey like with spider web or cotton candy growth is ideal.

-

Collected IMO should smell like yeast.

- If rain has entered the box, the contents should be discarded and the process repeated.

- Black molds on the steamed rice indicate that you have exceeded the number of days

-

If the mold is a color other than white (other colors indicate growth of less effective fungi).

How to make IMO2 by Chris Trump

Chris Trump - How to: IMO2

Chris Trump - How to: IMO2

Culturing and making IMO 2

Once collected this is referred to IM01. The next step is to culture and increase the population of this collection of Indigenous Microorganisms and create IMO2.

Materials to use:

- A clean clay pot (hard-fired, glazed, or terra cotta)

- A wooden spoon

- white paper towels

- rubber bands

- A large clear bowl, big enough to hold contents of rice mixture

- A small food scale

- A straw mat

- A shovel

- A composting thermometer

-

Raw, granulated brown sugar is advisable, but crude and unrefined sugar (jaggery) is better.

- The closer the state of sugar is to nature, the better. The less process the sugar has undergone, the more effective it is. Therefore, white refined sugar is not recommended.

- Wheat mill run* or, if available, mushroom growth medium waste.

Mixing Process

-

Tare the scale for the mixing jar.

- Weigh the filled bowl and calculate the weight of the rice mass by subtracting the weight of the empty bowl from the filled bowl.

-

Weight out equal amounts of sugar to the amount of molded rice.

- The use of sugar is used for osmotic pressure and not as a food source.

-

Gradually mix 1 to 1 with sugar or Jaggery.

-

You can mix IMO collections.

- Diversity is a strength in natural farming.

- This will put the microbes into a dormant state for later use.

-

Hand knead and massage, not smashing hard the sugar and rice until the material has the consistency of gooey molasses.

- It is ok to mix in more brown sugar if the mix is too wet.

-

If it starts to bubble you have lost quality and will not be as effective.

- This is from being too wet and it started to ferment.

-

Place the mixture in jar 2/3 full.

- Use the wooden spoon to move the molded rice into the jar.

- The 1/2 air space is necessary for the process.

- Clean the top of the container with vinegar.

-

You can mix IMO collections.

- Cover it with paper towel secured in place with rubber bands.

-

Store the pot in a cool area away from direct sunlight for 7 days.

- This will allow the mixture to ferment.

-

Working in a shaded area:

- Add a small amount of water to the fermented rice mixture in a 1:500 ratio.

-

Then, slowly blend in wheat mill run (or used mushroom medium) until mixture is of semi-moist but not wet consistency

- 65–70% moisture content of the media mixture.

-

Place a mound of the mixture on a soil surface and cover it.

- Use a tarp, straw mat or leaves, protecting it from sunlight.

- Allow the microbes to propagate for 7 days.

-

Periodically examine the external surface of the pile for white mold growth,

- monitor internal temperature of the pile with a composting thermometer so as not to exceed 122°F (50°C),

- Turn the pile with a shovel (a minimum of three to four times during the week) to keep fermentation temperatures from getting too high.

-

When the fermentation process is finished,

- internal temperature will stabilize, indicating cultivation is complete and ready to use.

Application and use

This biological soil amendment is expected to enhance soil microorganism activity. This is a concentrated inoculate.

- Dilute the final product (1 to 1 by volume) with soil and incorporate this mixture into the surface soil as a topdressing for crop production,

- Add it to your compost pile.

- Further processing into into IMO3.

Congratulations for learning about IMO 1 & 2

Credits

- EnigmaVEVO

- Chris Trump

-

KNF Journey

- Guardeners of the Land

- Gabriel Greiner

- Cho Global Natural Farming(CGNF)

- University of Hawaii

- Gil A. Carandang Herbana Farms Burol, Calamba City Laguna, Philippines

Natural Farming Inputs

- Introduction to Natural Farming

- LAB - Lactic Acid Bacteria

- FPJ - Fermented plant juice

- Seawater, Fermented Seawater, Bio Mineral Water

- Vinegar

- OHN - Oriental Herbal Nutrient

- WCA - Water Soluble Calcium

- WCAP - Water Soluble Calcium Phosphate

- FFJ - Fermented Fruit Juice

- FAA - Fish Amino Acids

- S.E.S. - Seed and Seedling Treatment

- IMO to IMO2

- IMO 3

- IMO 4 & Liquid IMO

- IMO 5

- Preserving bacterial based inputs

~ A Proud Cultural Healing and Life Compilation

-

Natural Farming Inputs

- Introduction to Natural Farming

- LAB - Lactic Acid Bacteria

- FPJ - Fermented plant juice

- Seawater, Fermented Seawater, Bio Mineral Water

- Vinegar

- OHN - Oriental Herbal Nutrient

- WCA - Water Soluble Calcium

- WCAP - Water Soluble Calcium Phosphate

- FFJ - Fermented Fruit Juice

- FAA - Fish Amino Acids

- S.E.S. - Seed and Seedling Treatment

- IMO to IMO2

- IMO 3

- IMO 4 & Liquid IMO

- IMO 5

- Preserving bacterial based inputs

Inputs - Section 9

S.E.S. - Seed and Seedling Treatment

Reggaeville - Sistah Awa - Roots and Culture

About S.E.S.

Reggaeville - Sistah Awa - Roots and Culture

About S.E.S.By utilizing vinegar, OHN and FPJ at the right ratios and soaking for effective periods of time based on seed size and germination period (short, medium and long) the natural farming input seed and seedling treatment (SES) will work to ensure that planted seeds and transplanted trees and bushes start off with strong vigor and a healthy start.

- This solution is extremely powerful. The difference in seed shape as well as root development and in leaf thickness is easily visible.

Chris Trump video on S.E.S.

Chris Trump - How To: Seed Treatment Solution S.E.S.

Chris Trump - How To: Seed Treatment Solution S.E.S.

Materials

-

Vinegar

- Brown rice vinegar or apple cider vinegar is typical but any fermented vinegar can be used.

- Helps break up the cotyledon

-

FPJ

- Is used to add heath and vigor.

-

OHN

- Is used for good redevelopment and pest resistance.

-

Water

- A mineral rich water is ideal or a diluted seawater.

- Regular water without chlorine is fine.

Instruction for making SES.

- Mix together the vinegar and FPJ with water at a dilution of 1 to 500.

-

Mix OHN with water at a rate of 1 to 1000.

- The dilution rate is weaker than vinegar and FPJ.

- If you have year old OHN dilute a bit more as OHN strengthens over time.

-

Once mixed, you can store SES in a sealed jar until ready to use.

- Store out of direct sunlight.

Instruction for seeds

-

Soak seeds by size and time of germination.

- Seeds which germinate quickly (turnip, chinese cabbage, bean) should be soaked for 10 minutes to two hours;

- Seeds which germinate more slowly (cucumber, melon, squash, lotus) should be soaked for 20 minutes to four hours.

- Seeds which germinate very slowly (rice, barley, tomato) should be soaked for 30 minutes to 7 hours.

- A half to one hour is sufficient for potatoes, ginger, taro and garlic.

- Plant the seeds while wet and do not allow to dry.

Instruction for Seedlings and potted plants.

-

In 3 liters of water mix 2 tablespoons of vinegar, 2 tablespoons of FPJ and 2 tablespoons of OHN.

- OHN is higher as the plants are seedlings or established plants rather than seed.

- Before transplanting seedlings do not water for 2 days.

-

Remove dirt by gently shaking, try not to damage the roots.

- You can also rinse the soil off from roots.

-

Tree transplants, remove any dirt.

- Can use water to rings soil away.

-

Allow roots to dry two days.

- This ensures the plant will strongly uptake the SES solution.

- Soak for desired time.

- Put in a container and soak the seedlings for 15 seconds.

- Immediately transplant the seedlings.

- The seeds will develop thick cotyledons making it immune to worms.

- They will also have good root development making them resistant to diseases.

- Foliar spray the remaining mixture on plants after they are transplanted.

Credits

- Chris Trump

- https://rooftopecology.wordpress.com

- http://www.cgnfindia.com/index.html

- The School of Life

- Reggaeville - Sistah Awa

Congratulations for learning about S.E.S.

Natural Farming Inputs

- Introduction to Natural Farming

- LAB - Lactic Acid Bacteria

- FPJ - Fermented plant juice

- Seawater, Fermented Seawater, Bio Mineral Water

- Vinegar

- OHN - Oriental Herbal Nutrient

- WCA - Water Soluble Calcium

- WCAP - Water Soluble Calcium Phosphate

- FFJ - Fermented Fruit Juice

- FAA - Fish Amino Acids

- S.E.S. - Seed and Seedling Treatment

- IMO to IMO2

- IMO 3

- IMO 4 & Liquid IMO

- IMO 5

- Preserving bacterial based inputs

~A Cultural Healing and Life Compilation

-

Natural Farming Inputs

- Introduction to Natural Farming

- LAB - Lactic Acid Bacteria

- FPJ - Fermented plant juice

- Seawater, Fermented Seawater, Bio Mineral Water

- Vinegar

- OHN - Oriental Herbal Nutrient

- WCA - Water Soluble Calcium

- WCAP - Water Soluble Calcium Phosphate

- FFJ - Fermented Fruit Juice

- FAA - Fish Amino Acids

- S.E.S. - Seed and Seedling Treatment

- IMO to IMO2

- IMO 3

- IMO 4 & Liquid IMO

- IMO 5

- Preserving bacterial based inputs

Inputs - Section 8 -

FAA - Fish Amino Acids

The Fish Amino Acid (FAA) is a liquid made from fish and used largely in the vegetative state.

FAA is of great value to both plants and microorganisms in their growth, because it contains and abundant amount of nutrients and various types of amino acids (will constitute a source of nitrogen (N) for plants).

FAA is used in conjunction with other Natural Farming inputs and applied as either a light foliar mist or a soil drench to maximize uptake and minimize runoff or leaching, providing just enough N to the plant for optimum uptake and the production of chlorophyll to maintain plant health.

PDF - University of Hawaii

Videos of Fish Amino Acid FAA Recipe

Chris Trump - FAA and Fermented Compost

#Christrump #soilsmith #naturalfarming Korean Natural Farming How to: FAA

Drake - CGNF Fish Amino Acid FAA recipe

Drake - CGNF Fish Amino Acid FAA recipe

FAA video with great information

Hybrid Agri - Hybrid Tutorial: How To Make FAA Fish Amino Acids for Organic Gardening

Hybrid Agri - Hybrid Tutorial: How To Make FAA Fish Amino Acids for Organic Gardening

Materials

- Fish trash (head, bone, intestine, etc.)

- Jagerry / Brown sugar / Molasses can be used.

- IMO-3 (for smell and to help dissolve fish fats)

- LAB (optional, for smell and to help dissolve fish fats)

- Mosquito net

- Rubber band / thread

- Clay pot / plastic jar (PE container) or glass jar

Instructions

-

Cut fish into pieces and put in a clay pot or plastic jar. Do not use hands.

- The smaller the pieces the easier it is to dissolve.

- All parts of fish are usable, tails, gills, guts, eggs, fins, heads, bones.

- Blue backed fish are best such as mackerels, sardines, skipjack tuna and similar.

- Place a layer of large rocks at the bottom to provide aeration, minor minerals, and an area where the liquids will collect during the fermentation process.

-

Add Jagerry of an equal amount (1:1 weight ratio).

- Molasses can also be used.

- Brown Sugar.

- Fill the jar up to 2/3 of its volume.

-

Add 2 to 3 tea spoons of IMO-4, and LAB to dissolve the fat.

- This will prevent a smell.

- Add a little OHN.

- Do not leave any fish exposed above the sugar.

- Cover the opening of jar with a breathable cover.

-

After approximately 3 to 5 days, the fish waste will begin to break down and liquefy through fermentation and the osmotic pressure generated by the addition of brown sugar.

- However, the process takes 2 to 6 months to produce mature FAA that is ready to use.

-

FAA, when completely fermented, will have a sweet, slightly fishy odor

- Big bubbles are indicative of a weak enzyme reaction.

- Small bubbles are indicative of a strong enzyme reaction.

-

Drain and extract the solution.

- After small bubbles have stopped

-

Bottle and store.

- Leave lid loose for two weeks as to prevent pressure build up and a sticky explosion.

- Store in a cool dry place out of direct sunlight.

- The remaining solids can be used to make IMO#5 or composted.

Tips and use

- FAA is rich with nitrogen. It is good fertilizer for applying both to soil and foliage since it enhances the growth of crops during their vegetative growth period when used with other Natural Farming Materials.

-

When making IMO or mixed compost apply the FAA after diluting it with water 1:1000 ratio.

- Then the FAA will help activate the micro organisms.

-

For leafy vegetable, it is possible to use FAA continuously to increase yield and improve taste and fragrance.

- For leafy vegetables, spray weekly to improve yields, fragrance, and taste.

- Avoid spray applications during full sunlight hours to prevent foliar burning and evaporation of the solution before the plant has had a chance to absorb it.

- Do not use FAA during the reproductive growth stage as it may induce over growth and extend harvest dates.

-

Put the bones left over from creating FAA into the brown rice vinegar (BRV).

- The bones will decompose and produce a quality water-soluble calcium phosphate.

- Blue, back color fishes will make ideal FAA as they have high amounts of amino acid).

-

Mackerel FAA is very effective in getting rid of mites and the green house whitefly (Trialeurodes vaporariorum).

- Dilute FAA with water and spray it on both sides of the leaf.

- Do not use after the vegetative stage.

- The effects of FAA are more observable when mixed with a pinch of urea.

Study on rice grown with Natural Farming Fish Amino Acids.

Drake - ISNSF16 - Rice Growth w/ Fish Amino Acid - Julius Sugue

Drake - ISNSF16 - Rice Growth w/ Fish Amino Acid - Julius Sugue

Congrats for learning about FAA!

Credits

- #Christrump #soilsmith #naturalfarming

- Drake

- Hybrid Agri

- https://www.ctahr.hawaii.edu/

- Julius Sugue

- http://www.cgnfindia.com

- Monty Python

- The School of Life

Natural Farming Inputs

- Introduction to Natural Farming

- LAB - Lactic Acid Bacteria

- FPJ - Fermented plant juice

- Seawater, Fermented Seawater, Bio Mineral Water

- Vinegar

- OHN - Oriental Herbal Nutrient

- WCA - Water Soluble Calcium

- WCAP - Water Soluble Calcium Phosphate

- FFJ - Fermented Fruit Juice

- FAA - Fish Amino Acids

- S.E.S. - Seed and Seedling Treatment

- IMO to IMO2

- IMO 3

- IMO 4 & Liquid IMO

- IMO 5

- Preserving bacterial based inputs

~ A Cultural Healing and Life Compilation

-

Natural Farming Inputs

- Introduction to Natural Farming

- LAB - Lactic Acid Bacteria

- FPJ - Fermented plant juice

- Seawater, Fermented Seawater, Bio Mineral Water

- Vinegar

- OHN - Oriental Herbal Nutrient

- WCA - Water Soluble Calcium

- WCAP - Water Soluble Calcium Phosphate

- FFJ - Fermented Fruit Juice

- FAA - Fish Amino Acids

- S.E.S. - Seed and Seedling Treatment

- IMO to IMO2

- IMO 3

- IMO 4 & Liquid IMO

- IMO 5

- Preserving bacterial based inputs

Inputs - Section 7

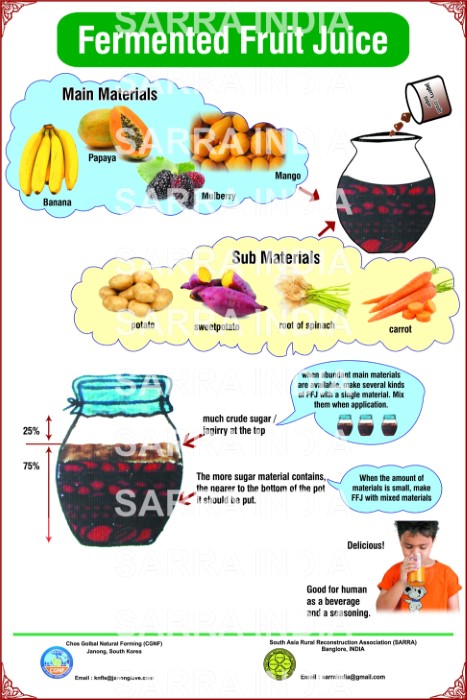

Fermented Fruit Juice

Fermented Fruit Juice or FFJ is is a water soluble potassium that is similarly made as Fermented Plant Juice (FPJ) but with fruit.

FFJ is easily absorbed by the plants leaf. It is basically an artificial honey as a nutritional activation enzyme which promotes growth, helps maintain a bio friendly environment, and helps animal digestion.

It is used to revitalize crops, livestock and for humans, as all natural farming input, it is edible. As the main fruit ingredients use sweet fruits such as Banana, Papaya, Mango, Grape, Melon, Apple etc (the fruits must be sweet and not tart or sour). However, only use citrus with other citrus plants.

Different types of FFJ can be made for different periods of plant growth. You can make a change over FFJ from unripe fruit. For periods of main flowering you can use riper fruit and for end of crop you use matured end of harvest fruits.

- In this way you can tailor an FFJ for the properties that match your specific growth period.

Aloha Terps - Korean Natural Farming - URBAN FORAGING FOR FFJ (fermented fruit juice)

Aloha Terps - Korean Natural Farming - URBAN FORAGING FOR FFJ (fermented fruit juice)

Instructions

-

Suggested materials include banana, papaya, pineapple, mango, jack fruit, star fruit, guava, pumpkin, etc

- (use citrus with only citrus plants and grapes only with grapes due to their cold weather and sour characteristics).

- Recommended “best” mixture is banana 3 kg, papaya 3 kg, and pumpkin 3 kg.

- Potato, cassava, yam, matured squash and carrot can be substituted for fruit if needed.

- Make FFJ from each fruit separate and mix before use. '

-

Prepare at least 3 fully ripened fruits, either picked or fallen.

- If the quantity of fruits is not sufficient, you may add supplementary ingredients such as spinach roots, wild yam, cabbage, cucumber, zucchini and radish. (Use grapes only for grapes and citrus for citrus fruits. These fruits are not good when used on other crops due to their cold and sour characteristics.)

- Do not wash the fruit.

- Best time to prepare in the evening to prevent flying insect.

-

Generally prepare 1 kilo fruits to 1 kilo brown sugar or in a 1 to 1 ratio

- Use half of the sugar while dicing and pour the remaining half after all of the fruits have been diced and placed in the container.

- In summer for 1 Kg of fruit ingredient, use 1.2 to 1.3 Kg of brown sugar (Jaggery)

- In winter use 1Kg each of fruit and brown sugar or in a 1 to 1 ratio. (One of the functions of brown sugar is to control moisture. During winter, temperature is lower, thus, there is little need to control the moisture).

- Spread the sugar on the chopping board.

- Dice your fruit ingredients starting with the ripest.

-

After dicing, smear sugar on the fruits and put them in a container.

- This step should be taken quickly to prevent the loss of essential substances. Fruits that are difficult to dice like grapes and strawberries may be slightly crunched with clean fingers.

- Use half of the sugar while dicing and pour the remaining half after all of the fruits have been diced and placed in the container.

-

Slowly stir the mixture of diced fruits and sugar, about 2 to 3 times with a wooden stick.

- Stir more in winter as temperature plays a role in this process.

- Stir less in summer as temperature plays a role in this process.

-

Place in a jar and fill to 2/3 full leaving air for the fermentation to happen.

- Always leave 1/3 of the container or jar open so the organisms can breath.

-

Let sit 7 to 10 days out of direct sunlight and bright light.

- When big bubbles pop during the fermentation process, it means the power of enzyme is weak.

- When tiny bubbles fiercely boil at once, it means power of enzyme is strong.

- After fermentation, sprinkle some more sugar on the mixture and store in a cool and shaded place. It is normal, that some sugar can still be found on the surface.

- When storing, leave the lid loosely on for 14 days to prevent an explosion from gasses.

How and when to use

For Plants:

- Apply using 2 tbsp of FFJ / 10 liters of water. Apply directly to leaves of plants when sun is not out. Add to the IMO and FPJ mixture and spray together to the leaves and soil of fruit bearing trees or during vegetative and reproductive stages.

For Animals:

- Mix 2 tablespoons of the juice to 1 liter of water. This is also good for human consumption.

Transition/Changeover period:

- During this period, crops require ample amounts of phosphoric acid.

-

Acid from FFJs of less ripe fruits is good such as those from Papaya, Mulberry, Raspberry or grape.

- Only use grapes for grapes and citrus for citrus.

- Often used with other natural farming inputs.

-

After the Changeover period of crops:

- Apply with FFJ that has been diluted in 1:1000 ratio in water.

Reproductive growth period:

-

FPJs made from fully ripened fruits of apple, banana, mango, papaya, peach, and grape are useful to supply the calcium demand of crops at this stage.

- Often use with WCA and other inputs.

It is an excellent output for re-energizing crops and livestock.

- Spray it to chicken housing, vegetables, orchard for protection against diseases.

FFJ made from Strawberries

Nappy Valley Genetics #tastethenewbreed - Making nutrients Strawberry FFJ KNF Style. #breakawayfromthebottle

Nappy Valley Genetics #tastethenewbreed - Making nutrients Strawberry FFJ KNF Style. #breakawayfromthebottle

A video of fermented fruit juice production

UPOU Networks - Fermented Fruit Juice (Organic Agriculture)

UPOU Networks - Fermented Fruit Juice (Organic Agriculture)

Credits

- Of Monsters and Men

- Aloha Terps

- Nappy Valley Genetics #tastethenewbreed

- UPOU Networks

- The School of Life

Natural Farming Inputs

- Introduction to Natural Farming

- LAB - Lactic Acid Bacteria

- FPJ - Fermented plant juice

- Seawater, Fermented Seawater, Bio Mineral Water

- Vinegar

- OHN - Oriental Herbal Nutrient

- WCA - Water Soluble Calcium

- WCAP - Water Soluble Calcium Phosphate

- FFJ - Fermented Fruit Juice

- FAA - Fish Amino Acids

- S.E.S. - Seed and Seedling Treatment

- IMO to IMO2

- IMO 3

- IMO 4 & Liquid IMO

- IMO 5

- Preserving bacterial based inputs

~A Cultural Healing and Life compilation

-

Natural Farming Inputs

- Introduction to Natural Farming

- LAB - Lactic Acid Bacteria

- FPJ - Fermented plant juice

- Seawater, Fermented Seawater, Bio Mineral Water

- Vinegar

- OHN - Oriental Herbal Nutrient

- WCA - Water Soluble Calcium

- WCAP - Water Soluble Calcium Phosphate

- FFJ - Fermented Fruit Juice

- FAA - Fish Amino Acids

- S.E.S. - Seed and Seedling Treatment

- IMO to IMO2

- IMO 3

- IMO 4 & Liquid IMO

- IMO 5

- Preserving bacterial based inputs

Inputs - Section 6

Water Soluble Calcium Phosphate (WCP)

The Water-soluble Calcium Phosphate (WS-CaPo) is extracted from the bone of vertebrate animals. WS-CaPo is an essential substance for plant growth and is widely distributed in the soil.

Calcium phosphate is insoluble in water, but soluble in acids: this property is used in Natural Farming. Calcium phosphate can dissolve slightly in the water containing CO2.

WCP is great for building strength and for using during times of pregnancy.

Video by OneDrive, he speaks on WCA and WCAP.

He has so much information I recommend watching it if you have not.

Video By Chris Trump and illustrates the bones very well.

Chris Trump - How to WCAP

Chris Trump - How to WCAP

Drake discusses calcium phosphate with other additional information.

Drake - farmLife: water soluble calcium phosphate natural farming

Drake - farmLife: water soluble calcium phosphate natural farming

Instructions for WCP

Ingredients Needed

- Animal bones 200 gms (Cow / Pig / Chicken/ fish)

- Brown Rice Vinegar 1 liter. (BRV)

- Clay Jar / Glass Jar

- Porous paper ( Paper towel)

- Rubber Band

-

Ready the bones and remove all bits of food and leave only bone. (Pig, chicken and fish bones are common)

- Boil the bones and let dry in sunlight.

- Break the bone/shells into small pieces

- Lightly roast or grill the bone in a frying pan or foil container over low heat for approximately 45 minutes to remove any organic substances that will rot and contaminate the WCP.

-

Bones should be dry burned black all the way through but not ashed or tanned from being under done. Should almost look like charcoal.

- Shells do not need cooked.

-

Add the charred bone to a glass jar filled 2/3 full with brown rice vinegar, a store bought fermented vinegar will work just as well at a 1:10 ratio by weight.

- Vinegar should not be distilled.

- The vinegar and material will make carbon dioxide bubbles, while the calcium is being dissolved into the solution.

- Cover the mouth of the jar with breathable cloth, such as muslin, or paper (not plastic) and secure with rubber bands or ties to keep out pests.

-

Place the jar out of sunlight and bright lights for 7 to 10 days.

- Letting it sit longer than needed will not hurt the WCAP.

-

After this time, check if bubbles are present in the solution.

- If bubbles are not present, the WCP is “saturated” – proceed to step 10.

- If bubbles are present, add more roasted bones or shells and let stand for 1 to 2 more days.

- Repeat until the solution stops producing bubbles.

- Strain the vinegar-and-bone solution through a colander into a clean glass jar to remove eggshells.

- Label the WCP solution and store at room temperature out of direct sunlight.

- compost the remaining materials.

Preparation of 1:1,000 WCP Solution

Amount of WCP _____________________________________________________________

Water Volume Kitchen utensil measurements Fluid ounces (fl oz) Milliliters (ml)

¼ gallon 1 /3 teaspoon (tsp) 0.06 2

1 gallon ¾ tsp 0.13 4

5 gallons 1¼ tablespoons (Tbsp) 0.64 19

10 gallons 2½ Tbsp 1.28 38

25 gallons little less than ½ cup 3.2 95

50 gallons little more than ¾ cup 6.4 189

Applying and when to use WCP

-

Apply WCP during the Change-over period.

- It promotes the differentiation of flower buds resulting in high fertility and yield.

- WCP improves the sugar content of fruits.

- Apply WCP when the colors of leaves turn light or dark green.

- WCP can easily travel within the plant and move to the vigorous new leaves first. As a result, symptoms of deficiency appear mainly on the petiole and veins of the old leaf.

- The new leaf does not grow well and it becomes smaller and dark green in color.

- The growth of flowers is noticeably suppressed, naturally bearing fewer fruits.

- The fruit skin becomes thick and the acid content increases.

-

Dilution rate of 1:500

- During transition stage.

- Using with pregnant animals.

- Dilution rate of 1:1000 when mixing with water soluble calcium inputs.

Congratulations for learning about WCP

Credits

- Onedrive

- Chris Trump

- Drake

- Run River North

- Reggaeville - Sistah Awa - Roots and Culture

- The School of Life

Natural Farming Inputs

- Introduction to Natural Farming

- LAB - Lactic Acid Bacteria

- FPJ - Fermented plant juice

- Seawater, Fermented Seawater, Bio Mineral Water

- Vinegar

- OHN - Oriental Herbal Nutrient

- WCA - Water Soluble Calcium

- WCAP - Water Soluble Calcium Phosphate

- FFJ - Fermented Fruit Juice

- FAA - Fish Amino Acids

- S.E.S. - Seed and Seedling Treatment

- IMO to IMO2

- IMO 3

- IMO 4 & Liquid IMO

- IMO 5

- Preserving bacterial based inputs

~cultural Healing and Life compilation

-

Natural Farming Inputs

- Introduction to Natural Farming

- LAB - Lactic Acid Bacteria

- FPJ - Fermented plant juice

- Seawater, Fermented Seawater, Bio Mineral Water

- Vinegar

- OHN - Oriental Herbal Nutrient

- WCA - Water Soluble Calcium

- WCAP - Water Soluble Calcium Phosphate

- FFJ - Fermented Fruit Juice

- FAA - Fish Amino Acids

- S.E.S. - Seed and Seedling Treatment

- IMO to IMO2

- IMO 3

- IMO 4 & Liquid IMO

- IMO 5

- Preserving bacterial based inputs

Inputs - Section 5 - Water Soluble Calcium (WCA)

Calcium is as important to plants as it is to humans. It is one of the most common substances in the world next to oxygen and silicon and the majority of calcium exists in the form of calcium carbonate (CaCO3).

In Natural Farming, calcium carbonate is extracted from egg shells, shells from clams/oysters or from coral sand in which calcium carbonate is the main component by using a vinegar. Through this process, calcium carbonate is changed to water-soluble calcium, which can be quickly absorbed by the crop.

- It prevents overgrowth of crops, hardens the fruit, prolongs storage period, promotes absorption of phosphoric acid and helps crops to accumulate nutrients.

- Calcium carries and accumulates nutrients carbohydrate, which is temporarily stored in branches (pith) and in leaves till the final storage.

Several soil characteristics affect the availability of calcium to plants:

-

soils with higher pH have higher levels of available calcium than acidic (lower-pH) soils; soils with a higher capacity to absorb or hold calcium will have more available calcium;

- the presence of excessive amounts of sodium, potassium, or magnesium in the soil interferes with calcium availability.

- Calcium can also react with other soil nutrients, such as phosphorus, to form insoluble compounds that cannot be used by plants.

- Calcium is commonly applied as a soil amendment in the form of ground limestone (calcium carbonate) or gypsum (calcium sulfate).

Water-soluble calcium (WCA) is an alternative to these commercial sources of calcium.

- Water-soluble calcium is a source of available calcium that can be made from commonly used household items, eggshells and from the shells of clams/oysters and vinegar.

When applied as a foliar spray, WCA provides available calcium to plants for normal cell processes, root growth, and fruiting

- In Natural Farming, WCA is applied as a foliar spray during the reproductive stage of a plant’s growth cycle when setting fruit and vegetables are most vulnerable to blossom-end rot.

- Calcium in water soluble form is efficient and effective

- WCA is also effective when crops are overgrown,

- Plant leaves have bad color or no luster,

- Floral differentiation is weak,

- Flower blossoms just fall,

- Fruits do not ripen,

- Fruits are not sweet and crops are nitrogen-excessive.

- However, WS-Ca should not be given when vigorous vegetative growth is needed.

Master Cho Recipe

PDF - WCA

WCA video by Onedrive

WCA with eggshells by Chris Trump

Chris Trump - WCA with eggshells - https://www.patreon.com/christrump

Chris Trump - WCA with eggshells - https://www.patreon.com/christrump

Instructions for WCA

Collect eggshells (oyster or clam shells may also be used);

- Remove the tough internal membrane from the inside of the shells.

- Break the shells into small pieces (1/4”).

-

Lightly roast or grill the shells in a frying pan or foil container over low heat for approximately 45 minutes to remove any organic substances that will rot and contaminate the WCA.

-

You can fan over top the eggshells while cooking to remove the unwanted egg lining.

- the wind from fanning will blow them away.

-

You can fan over top the eggshells while cooking to remove the unwanted egg lining.

- Shells should be dry and lightly burnt to a light tan color but not charred.

-

Slowly add roasted eggshells to a glass jar filled 2/3 full with brown rice vinegar, a store bought fermented vinegar will work just as well at a 1:10 ratio by weight.

- Vinegar should not be distilled.

- Add eggshells slowly or the solution can over foam and create a mess.

- The eggshell fragments will float up and down within the vinegar, emitting carbon dioxide bubbles, while the calcium is being dissolved into the solution.

- Cover the mouth of the jar with breathable cloth, such as muslin, or paper (not plastic) and secure with rubber bands or ties to keep out pests.

-

Place the jar in a cool, dark location for 7 to 10 days.

- Letting it sit longer than needed will not hurt the WCA.

-

After this time, check if bubbles are present in the solution.

- If bubbles are not present, the WCA is “saturated” – proceed to step 10.

- If bubbles are present, add more roasted eggshells and let stand for 1 to 2 more days.

- Repeat until the solution stops producing bubbles.

- Strain the vinegar-and-eggshell solution through a colander into a clean glass jar to remove eggshells.

- Label the WCA solution and store at room temperature out of direct sunlight.

- compost the remaining eggshells.

Preparation of 1:1,000 WCA Solution

Amount of wca _____________________________________________________________

Water Volume Kitchen utensil measurements Fluid ounces (fl oz) Milliliters (ml)

¼ gallon 1 /3 teaspoon (tsp) 0.06 2

1 gallon ¾ tsp 0.13 4

5 gallons 1¼ tablespoons (Tbsp) 0.64 19

10 gallons 2½ Tbsp 1.28 38

25 gallons little less than ½ cup 3.2 95

50 gallons little more than ¾ cup 6.4 189

WCA with Coral Sand

- Using coral sand is the easiest WCA method as their is no cooking off the shells needed.

Chris Trump teaches WCA with coral sand.

Chris Trump - How to WCA with Chris Trump - https://www.patreon.com/christrump

Chris Trump - How to WCA with Chris Trump - https://www.patreon.com/christrump

WCA Coral Sand instructions

(Oyster and clam shells can be used too)

-

Add coral sand to jar.

- one part coral sand to 10 parts vinegar.

-

Add vinegar slowly to the jar to prevent overflowing of bubbling.

- Use a fermented vinegar and not a distilled vinegar.

-

Cover the mouth of the jar with breathable cloth, such as muslin, or paper (not plastic) and secure with rubber bands or ties to keep out pests.

- Do not have air tight or it will explode from pressure build up.

-

Place the jar in a cool, dark location for 7 to 10 days.

- Letting it sit longer than needed will not hurt the WCA.

-

After this time, check if bubbles are present in the solution.

- If bubbles are not present, the WCA is “saturated” – proceed to step 6.

- If bubbles are present, add more coral sand and let stand for 1 to 2 more days.

- Repeat until the solution stops producing bubbles.

- Strain the vinegar-and-coral sand solution through a colander into a clean glass jar to remove coral sand.

- Label the WCA solution and store at room temperature out of direct sunlight.

- compost the remaining coral sand.

- Use same as WCA made with eggshells.

Reverend Peyton's big damn band sings us out!

bigdamnbandofficial - This land is your land solo slide guitar.